Description

Location: Germany, Baden-Württemberg Southwest

Zustand: Used

Hersteller: LANG

Modell: LANG

Year of construction: 2005

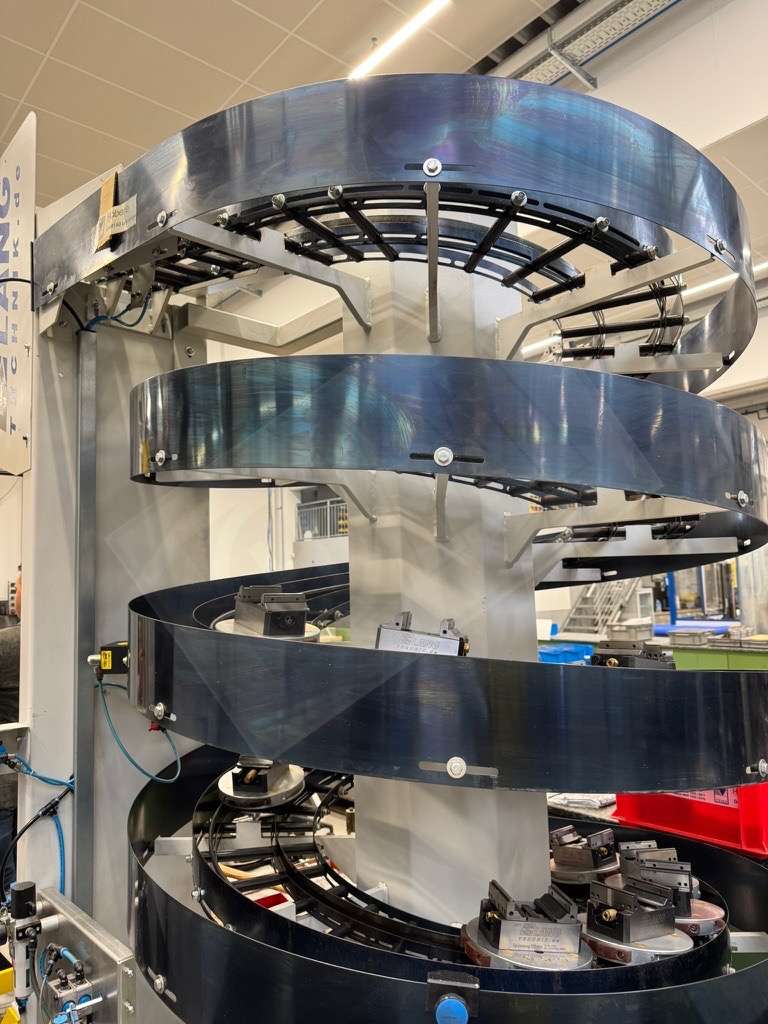

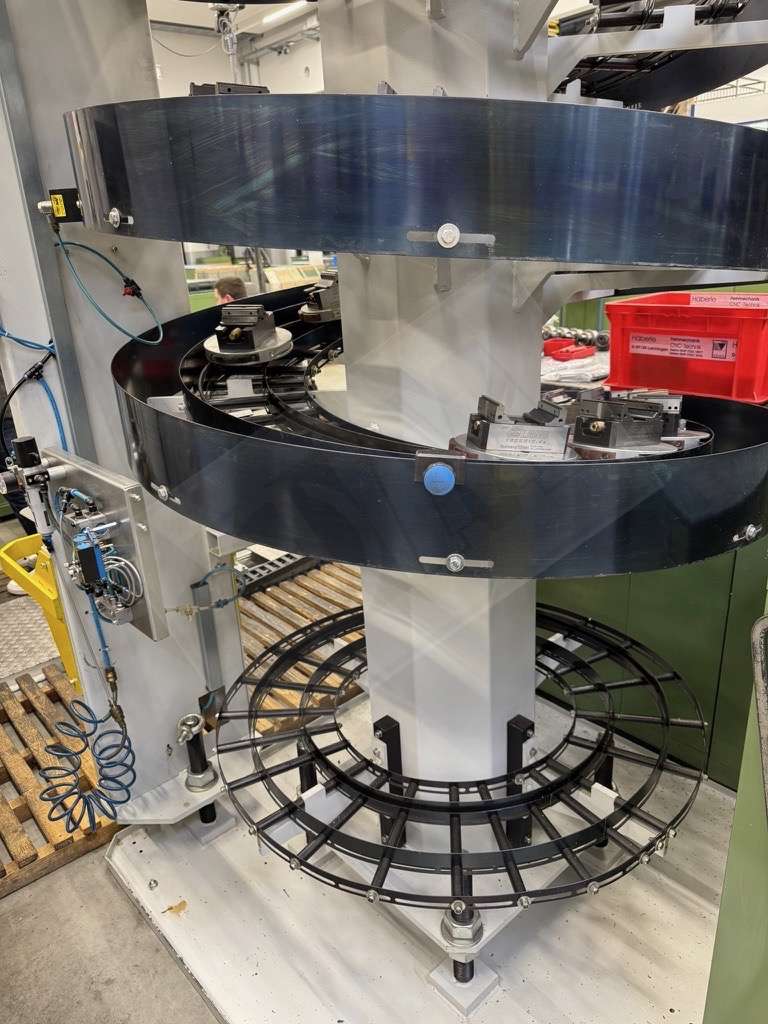

LANG Technik storage and feeding system built in 2005, incl. 20 vices

Automation system with chute arrangement Storage capacity of approx. 50-60 clamping vices.

Technical description:

LANG Technik stockpiling and feeding system

LANG Technik automation system with chute arrangement is an advanced automated workpiece handling and machining solution specifically designed for the efficient and precise management of clamping vices. Built in 2005, this system is designed to automate production processes and increase efficiency by optimising workpiece handling and reducing manual intervention.

Sliding arrangement:

The automation system is equipped with a chute arrangement that enables continuous, safe and fast unloading and transport of workpieces. The chutes serve as a connecting element between the various processing stations and are specially designed to ensure stable and precise movement of the workpieces throughout the entire production process.

Control system: The slide arrangement is coordinated via the system's central control unit so that operation is fully automatic and efficient.

- Storage capacity: approx. 50-60 clamping vices

- Slide material: steel or aluminium, depending on application

- Automation: Fully automated with central control unit

- Area of application: For processing workpieces of various sizes and shapes

- Application: Particularly suitable for metalworking and industrial production

- Integration: Easy to integrate into existing production processes

The machine can be inspected under power by appointment.

Subject to changes and errors in the technical data and specifications as well as prior sale!

LANG Technik storage and feeding system built in 2005, incl. 20 vices

Automation system with chute arrangement Storage capacity of approx. 50-60 clamping vices.

Technical description:

LANG Technik storage and feeding system

LANG Technik automation system with chute arrangement is an advanced automated workpiece handling and processing solution specifically designed for the efficient and precise management of vices. Built in 2005, this system is designed to automate production processes and increase efficiency by optimising workpiece handling and reducing manual intervention.

Chute arrangement:

The automation system is equipped with a chute arrangement that enables continuous, safe and fast unloading and transport of workpieces. The chutes serve as a connecting element between the various processing stations and are specially designed to ensure stable and precise movement of the workpieces throughout the entire production process.

Control: The chute arrangement is coordinated via the system's central control unit so that operation is fully automatic and efficient.

- Storage capacity: approx. 50-60 clamping vices

- Slide material: Steel or aluminium, depending on the application

- Automation: Fully automated with central control unit

- Area of application: For processing workpieces of various sizes and shapes

- Application: Particularly suitable for metalworking and industrial production

- Integration: Easy to integrate into existing production processes

The machine can be inspected under power by appointment.

Subject to changes and errors in the technical data and information as well as prior sale!